We need a technical consultant to answer your questions?

TEL:+86 17719986188

E-mail:liam@cnshanling.com

Address: Industrial Cluster Zone of Xiuwu Economic Development Zone, Jiaozuo City, Henan Province

Fine sand recovery device

Key words:

Fine sand recovery device

- Product Description

- Detailed parameters

-

- Commodity name: Fine sand recovery device

PRODUCT INTRODUCTION

The Fine Sand Recovery Unit is designed by our company through absorbing advanced foreign technologies and integrating China's actual conditions. It is widely used in water conservancy & hydropower projects, glass plants, fine aggregate recovery in building materials, coal slurry recovery in coal preparation plants, and environmental protection projects (such as sludge purification).

PERFORMANCE FEATURES

In traditional processes using spiral sand washers for desliming and dewatering, sand loss (especially fine sand) was almost uncontrollable. This recovery unit can effectively reduce fine sand loss to 5-10%, significantly decrease stone powder content in tailwater. It successfully solves the problems of high fineness modulus and low stone powder content in artificial aggregate processing systems, greatly improves manufactured sand quality, optimizes sand gradation, and addresses environmental pollution and discharge issues.

WORKING PRINCIPLE

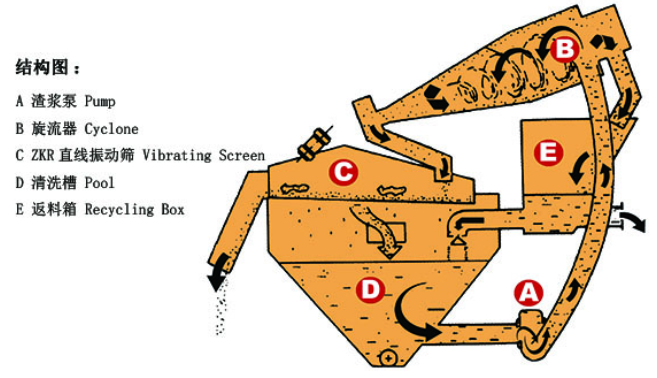

1、System Structure: Consists of motor, slurry pump, cyclone separator, ZKR linear vibrating screen, washing tank, and return box.

2、Operation Process: The sand-water mixture is delivered to the cyclone separator. Centrifugally classified and concentrated fine sand is fed to the vibrating screen through the sand sink nozzle. After dewatering by the vibrating screen, fine sand is effectively separated from water. Residual sand/sludge returns to the washing tank via the return box, with excess liquid discharged through the outlet when tank level is too high. The linear vibrating screen achieves 70%-85% solid concentration. Fineness modulus can be adjusted by modifying pump speed, slurry density, overflow water volume, or replacing sand nozzles. This system integrates three functions: washing, dewatering and grading.

-

Model

Pump

Cyclone Specification

Dehydration Belt

Capacity (m³h)

Power (kw)

Size

Model

Area (m²)

Power (kw)

SL-06-300

7.5

2"

300

0.6×1.5

0.9

2×0.75

40-60

SL-08-300

15

2.5"

300

0.8×2.25

1.8

2×1.5

40-100

SL-10-350

18.5

3"

350

1.0×2.25

2.25

2×1.5

70-140

SL-12-550

37

5"

550

1.2×3.0

3.6

2×2.2

100-260

SL-14-750

45

6"

750

1.4×3.0

4.2

2×3

180-343

SL-14-750Ⅱ

55

6"

750

1.4×3.75

5.25

2×3.7

230-420

SL-16-950

55

8"

950

1.6×3.75

5.25

2×5.5

250-500

SL-16-2×550

55

10"

2×550

1.6×3.75

6.00

2×5.5

300-500

SL-18-2×750

75

10"

2×750

1.8×3.75

6.75

2×5.5

350-800

Product Message

Get in touch with our team in a timely manner and be happy You offer help

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.