We need a technical consultant to answer your questions?

TEL:+86 17719986188

E-mail:liam@cnshanling.com

Address: Industrial Cluster Zone of Xiuwu Economic Development Zone, Jiaozuo City, Henan Province

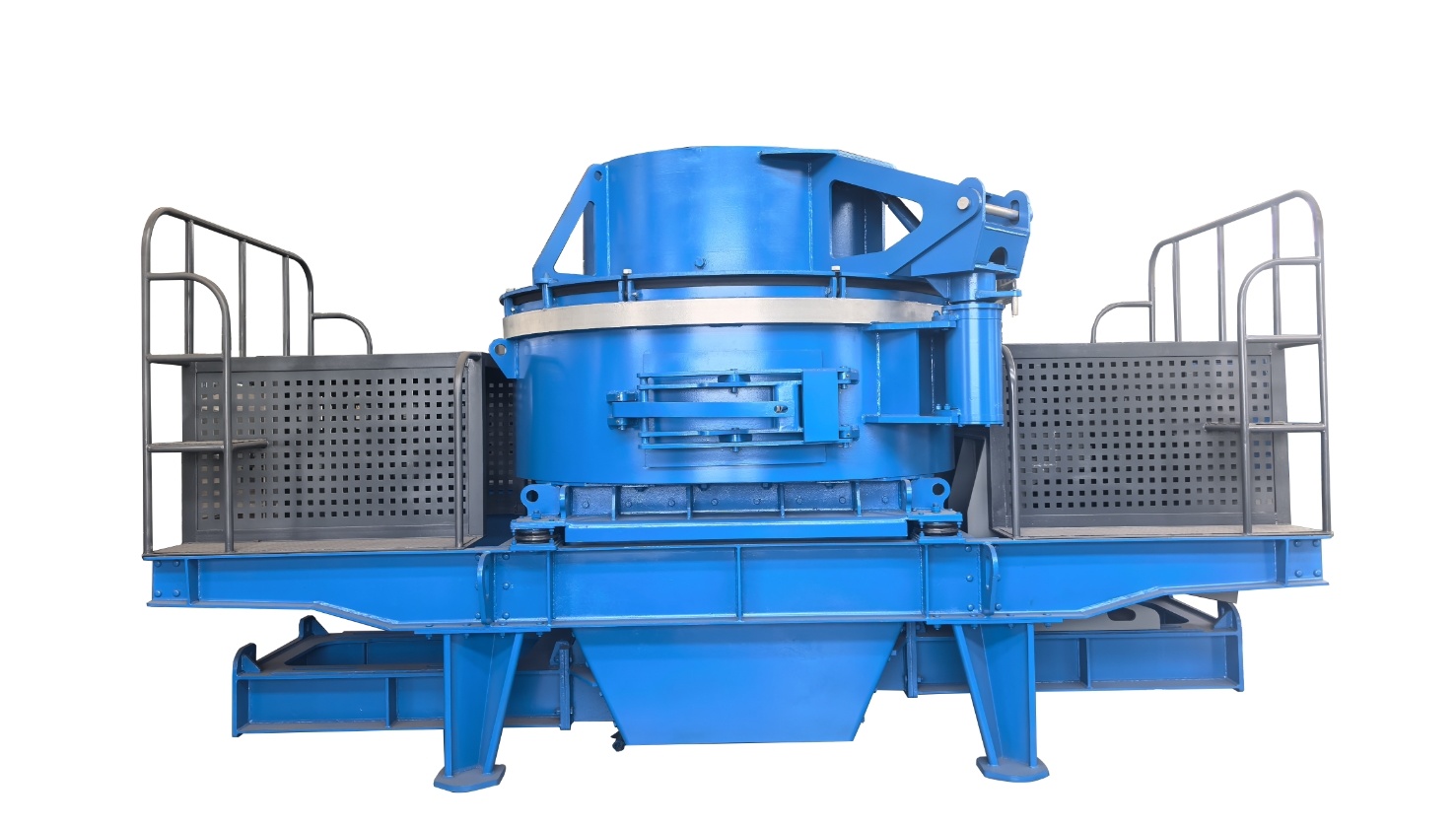

SL series stone shaping machine

Key words:

SL series stone shaping machine

- Product Description

- Detailed parameters

-

- Commodity name: SL series stone shaping machine

Product Introduction

The SL series stone shaping machine is a product developed by the company to help customers produce aggregates that meet national standards and achieve high acceptance rates. Its shaping design and manufacturing process incorporate advanced technologies from similar international products, resulting in a high-performance shaping equipment with internationally advanced technology. This machine adopts a new design concept, featuring excellent shaping capabilities, making it especially suitable for producing high-quality aggregates for high-grade highways, hydropower, airports, and construction. It offers superior advantages compared to other types of crushers.

Performance Characteristics

1. High output, excellent shaping function, good product shape;

2. Simple structure, easy installation and maintenance, low operating cost;

3. Strong ability to pass non-crushed materials, less affected by material moisture content, moisture content 7%;

4. Excellent product particle shape, cubic, very low needle and flake content, suitable for aggregate shaping and high-grade highway aggregate production;

5. High bulk density of the product, minimal iron contamination.

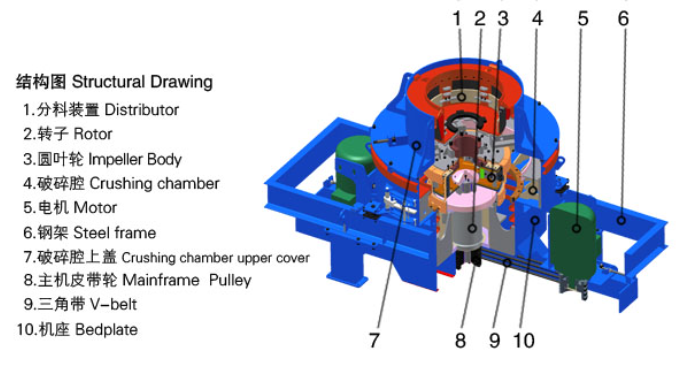

Working Principle

Materials vertically fall from the upper part of the machine into the high-speed rotating impeller. Under the action of high-speed centrifugal force, they collide and crush with another part of the material that is distributed in a umbrella-like form around the impeller. After mutual impact, the materials will repeatedly collide and rub between the impeller and the shell, forming a vortex flow, thus further crushing. The crushed materials are discharged directly from the bottom, forming a closed-loop multiple circulation, controlled by a screening device to achieve the required finished particle size.

-

model

Maximum feed size (mm)

Impeller speed (r/min)

Passage quantity (t/h)

Motor power (Kw)

SL-5000

40

1330-1530

80-150

180-264

SL-6000

40

1200-1400

120-250

264-320

SL-7000

40

1000-1200

180-350

400-500

SL-8000

40

1000-1100

250-500

500-560

SL-9000

40

1000-1100

400-650

560-630

Product Message

Get in touch with our team in a timely manner and be happy You offer help

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.