We need a technical consultant to answer your questions?

TEL:+86 17719986188

E-mail:liam@cnshanling.com

Address: Industrial Cluster Zone of Xiuwu Economic Development Zone, Jiaozuo City, Henan Province

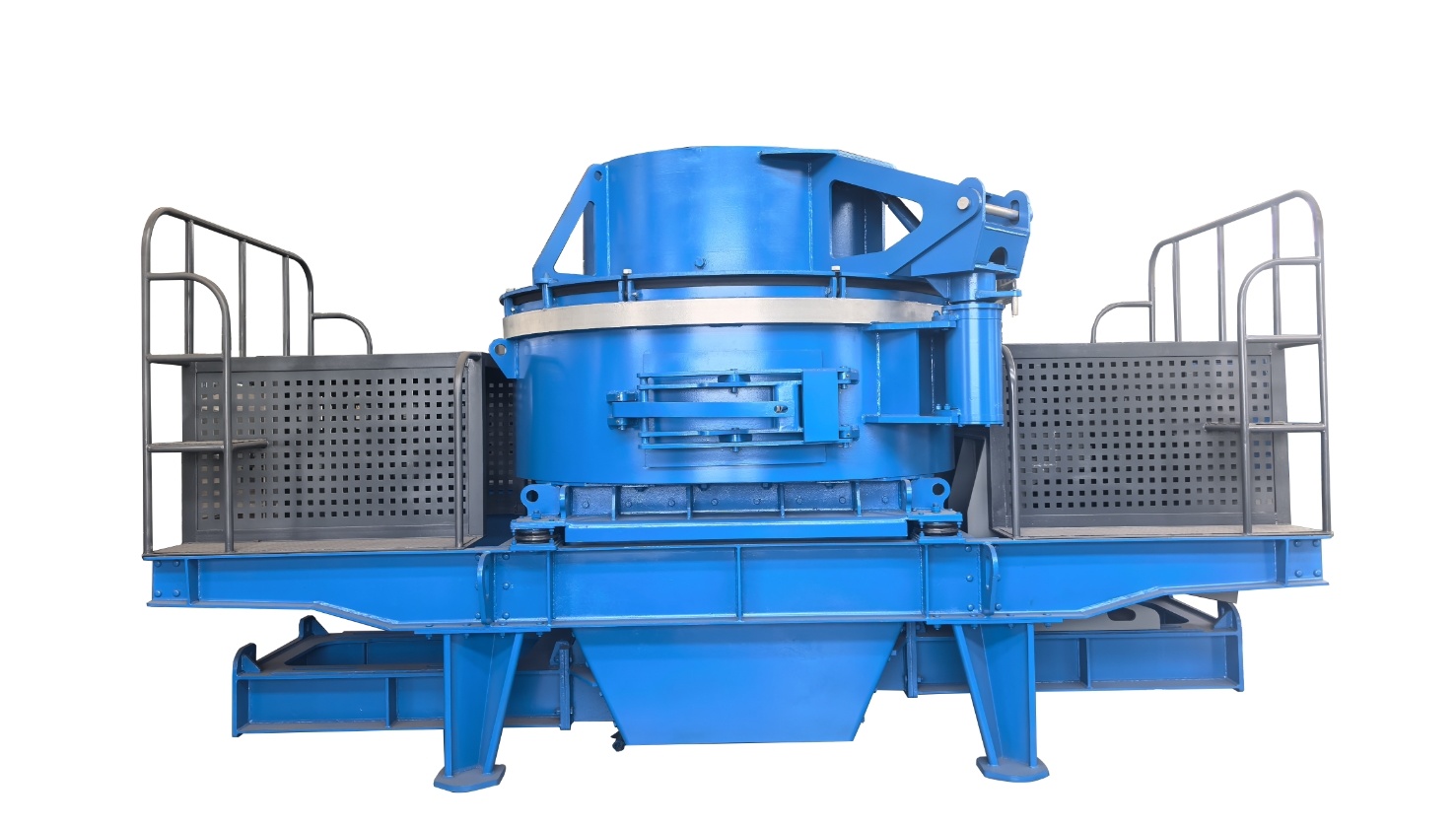

SL Series Vertical Impact Crusher

Key words:

SL Series Vertical Impact Crusher

- Product Description

- Detailed parameters

-

- Commodity name: SL Series Vertical Impact Crusher

Product Introduction

The SL series vertical impact crusher is a high-performance sand-making equipment with internationally advanced technology, researched and manufactured by our company by absorbing advanced foreign technologies. The machine has two forms: "stone-on-stone" and "stone-on-iron". The "stone-on-iron" type has a 10-20% higher sand making rate than the "stone-on-stone" type. This machine is widely used in the fine crushing and coarse grinding of metal and non-metal ores, building aggregates, cement, refractory materials, abrasives, glass raw materials, artificial sand and gravel, and various metallurgical slags. It can also be used for shaping high-grade highway pavement stone materials. It is particularly superior to other types of crushers for crushing medium-hard, extra-hard, and highly abrasive materials such as river pebbles, quartzite, sandstone, basalt, silicon carbide, diamond sand, and sintered alumina.

Performance Characteristics

1. High crushing efficiency, with fine crushing and coarse grinding functions;

2. Increased speed, larger crushing ratio, deep cavity rotor, higher output;

3. Simple structure, convenient installation and maintenance, low operating cost;

4. Optimized structure, energy-saving, low-carbon and more environmentally friendly;

5. Rare oil lubrication, multiple protective measures reduce equipment downtime, high degree of automation, and long service life;

6. Excellent product particle shape, cubic, very low needle and flake content, suitable for aggregate shaping, artificial sand making and high-speed highway aggregate production;

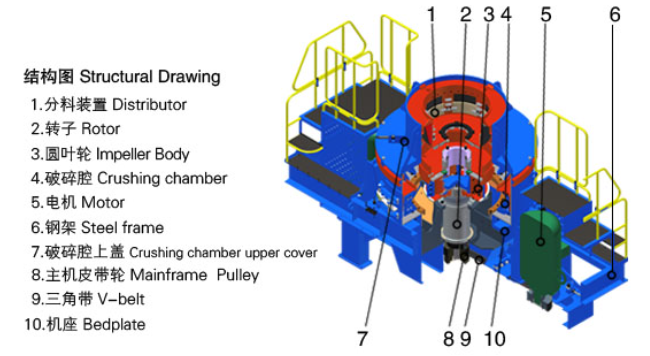

Working Principle

Round impeller stone-on-stone cavity

Applicable scope: All materials, especially highly abrasive materials

Usage characteristics: Closed round impeller plus stone-on-stone cavity configuration, with stone-on-stone crushing, low cost of wearing parts, and excellent product particle shape.

Round impeller stone-on-iron cavity

Applicable scope: Medium and low abrasive materials

Usage characteristics: Closed round impeller plus square impact plate configuration, with rotor grinding and high-efficiency crushing characteristics of the impact plate.

Open impeller stone-on-iron cavity

Applicable scope: Larger particle size, medium abrasive soft materials

Usage characteristics: Open impeller plus stone-on-iron cavity configuration, higher output and larger crushing ratio under the same conditions, larger feed size.

-

model

Maximum feed size (mm)

Impeller speed (r/min)

Processing capability (t/h)

Motor power (Kw)

External dimensions

(L×W×H)mm

All center feed

Add waterfall to the center

SLX-7515

40

1500-1920

50-100

100-180

2×75KW

4400×2251×2091

SLX-7518

40

1500-1920

60-120

120-240

2×90KW

4400×2251×2091

SLX-8522

40

1300-1780

80-150

160-280

2×110KW

4800×2360×2633

SLX-8526

40

1300-1780

130-190

220-360

2×132KW

4800×2360×2633

SLX-8532

40

1300-1780

150-230

260-450

2×160KW

4800×2360×2633

SLX-1140

40(50)

1200-1430

190-270

300-520

2×200KW

5850×2740×3031

SLX-1145

40(50)

1200-1430

250-360

350-580

2×220KW

5850×2740×3031

SLX-1150

40(50)

1200-1430

280-400

390-630

2×250KW

5850×2740×3031

SLX-1156

40(60)

1200-1430

350-450

430-750

2×280KW

5850×2740×3031

SLX-1263

40(60)

1100-1360

400-550

480-850

2×315KW

5700×2960×4186

SLX-1271

40(60)

1100-1360

460-630

520-950

2×355KW

6000×3039×3456

SLX-1280

40(60)

1100-1360

550-700

600-1080

2×400KW

6000×3039×3456

Product Message

Get in touch with our team in a timely manner and be happy You offer help

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.