We need a technical consultant to answer your questions?

TEL:+86 17719986188

E-mail:liam@cnshanling.com

Address: Industrial Cluster Zone of Xiuwu Economic Development Zone, Jiaozuo City, Henan Province

CH series single-cylinder cone crusher

Key words:

CH series single-cylinder cone crusher

- Product Description

- Detailed parameters

-

- Commodity name: CH series single-cylinder cone crusher

Product Introduction

Shanling's new high-efficiency single-cylinder hydraulic cone crusher, due to its high performance, high efficiency, reliability, and high cost-effectiveness, is widely used in construction, mining, building materials, metallurgy, water conservancy and other fields, such as the crushing of iron ore, copper ore, limestone, and granite materials.

By adopting advanced lamination crushing technology, the crushing particle size is uniform. This series of crushers can be fed and crushed according to customer's special requirements, effectively and reliably crushing to the specified particle size. It is easy to maintain, simple to operate, and can achieve high-yield production.

Performance Characteristics

Optimized cavity shape, higher output, better product quality

Low wear parts consumption, low operating cost

Easy conversion between coarse and fine crushing

Advanced hydraulic technology makes operation simple and maintenance convenient

Large feed opening design

Working Principle

The structure of the CH series single-cylinder hydraulic cone crusher makes the equipment easier to adjust. Even during operation, the discharge port can be easily adjusted. The intelligent automation control system ensures that the crusher is always in good working condition and realizes the automatic compensation function of the wear of the inner and outer cone liners. The discharge port size can be accurately set and adjusted from the control panel, and the wear compensation of the wear parts can be automatically completed by a few buttons on the control panel. At the same time, due to the adoption of a single-cylinder mechanical structure, the entire model is more compact, greatly reducing the number of oil pipes, oil circuits, and external adjustment structures.

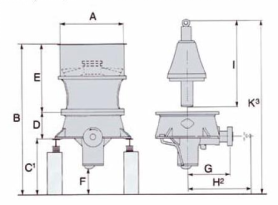

Size (mm)

Note: The reference lines (not the indoor floor) give the minimum dimensions for removal: 1 Hydroset system hydraulic cylinder, 2. Small gear shaft, 3. Main shaft

CH420

CH430

CH440

CH660

CH870

CH880

Φ1078

Φ1360

Φ1540

Φ1954

Φ2450

Φ2660

2560

2992

3410

4215

5475

6456

1020

1125

1300

1600

2200

2870

540

655

745

860

1228

1186

1000

1212

1365

1755

2045

2400

400

422

452

631

998

1151

843

1061

1280

1497

1824

2073

1270

1705

1900

2156

2850

3100

1425

1688

1985

2344

3095

3545

3000

3570

4000

4835

6600

7770

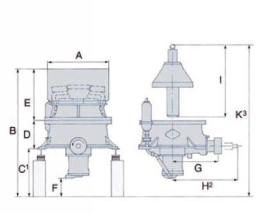

DIM.

CS420

CS430

CS440

CS660

A

Φ1285

Φ1635

Φ2000

Φ2800

B

2902

3485

4075

5100

C¹

1020

1125

1300

1600

D

540

655

745

860

E

1342

1705

2030

2640

F

400

422

452

631

G

843

1061

1280

1497

H²

1270

1705

1900

2156

I

1703

2050

2420

2895

K³

3600

4250

4930

5355

The dimensions in the table are for guidance only for pre-installation preparation and should not be used for foundation construction.

-

CH420

CH430

CH440

CH660

CH870

CH880

CS420

CS430

CS440

CS660

Maximum feed size (mm)

135

185

215

275

300

370

240

360

450

560

Discharge port range (mm)

4-35

5-38

6-44

10-51

10-70

8-70

19-38

19-51

25-54

38-83

Crusher weight (kg)

5300

9200

14300

23500

50000

66500

6800

12000

19300

36500

Motor power (kw)

90

132

250

315

520

600

90

160

250

315

Production capacity (t/h)

22-128

37-219

68-413

143-662

280-1512

309-2128

70-168

91-344

195-601

318-1050

Next

Product Message

Get in touch with our team in a timely manner and be happy You offer help

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.