We need a technical consultant to answer your questions?

TEL:+86 17719986188

E-mail:liam@cnshanling.com

Address: Industrial Cluster Zone of Xiuwu Economic Development Zone, Jiaozuo City, Henan Province

C series European version jaw crusher

Key words:

C series European version jaw crusher

- Product Description

- Detailed parameters

-

- Commodity name: C series European version jaw crusher

Product Introduction

The C series jaw crusher is a new generation of products successfully developed using the finite element analysis method, based on the design and manufacturing experience of Shanling jaw crushers and by introducing internationally advanced crushing technology and research results.

Compared with traditional jaw crushers, the C series jaw crusher pays more attention to details in design and manufacturing. It uses high-strength materials and advanced manufacturing processes, and has advantages such as higher structural strength, higher equipment reliability, larger crushing ratio, higher output, and lower comprehensive cost.

Performance Characteristics

1. Robust Structure

The frame is divided into two types: welded and assembled. Small and medium-sized specifications generally adopt welded type, while large-sized specifications generally adopt assembled type.

The welded type adopts a large-radius transition fillet and low-stress zone welding method, which greatly reduces stress concentration, ensures the equal strength of the frame in all directions, and has the characteristics of impact resistance, uniform stress, and low failure rate.

The assembled type adopts an advanced modular, weld-free frame structure design, with high fatigue strength and reliability. The entire machine's assembled design makes transportation and installation more convenient, especially suitable for installation in narrow and difficult-to-transport locations such as underground mines and high-altitude mountains.

2. Superior Cavity Design

Symmetrical "V" shaped cavity design, large inclination angle of the swing jaw, large stroke, and reasonable speed, resulting in larger feed size, higher output, more uniform particle size, and reduced jaw plate wear.

3. Durable Heavy-duty Swing Jaw Assembly

The heavy-duty swing jaw assembly uses a forged heavy-duty eccentric shaft, high-quality heavy-duty roller bearings, and a swing jaw body optimized by finite element software, ensuring high impact resistance and stability of the swing jaw assembly. The labyrinth seal and centralized lubrication system ensure that the bearing grease is not contaminated, making lubrication more convenient and resulting in longer and more stable operation.

4. Swing Jaw Guard Plate Design

A heavy-duty guard plate is installed above the swing jaw to effectively protect the swing jaw body and its internal bearings from damage caused by material impact.

5. Integral Bearing Housing

The integral cast steel bearing housing structure ensures complete matching with the frame, avoiding unnecessary radial loads on the bearings during the fastening process of a combined bearing housing, making the bearing operation smoother.

6. Convenient and Quick Particle Size Adjustment

The C series jaw crusher uses a mechanical or hydraulic discharge port adjustment device. Its double wedge block adjustment method is simpler, safer, faster, and saves downtime compared to the corresponding shim adjustment operation.

7. Integrated Motor Installation

The integrated installation of the motor seat and the crusher frame not only saves installation space for the jaw crusher and reduces the length of the V-belt, but also, due to the synchronous movement of the frame, motor seat, and motor, the adjustable motor seat achieves adjustment of the V-belt tension, thus extending the service life of the V-belt.

8. Shock Absorption Installation Design

The crusher is fixed using a special rubber shock absorber, which effectively absorbs the equipment's vibration peaks and allows vertical and longitudinal displacement of the crusher, thus reducing the impact on the foundation.

Working Principle

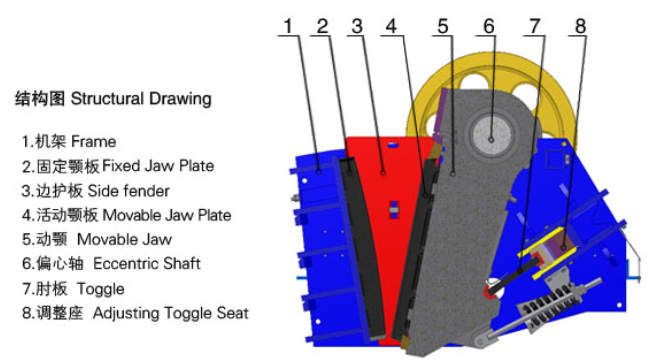

The motor drives the belt and pulley, and the eccentric shaft causes the swing jaw to swing back and forth. When the swing jaw pushes the swing jaw plate toward the fixed jaw plate, the material is crushed or split. When the swing jaw and swing jaw plate retreat under the action of the eccentric shaft and spring, the previously crushed or split material is discharged from the lower discharge port of the jaw plate. As the motor continuously rotates, the crusher's swing jaw periodically crushes and discharges material, achieving batch production.

Technical Parameters

-

Equipment model

MC80

MC96

MC106

MC100

MC116

MC3054

MC110

MC120

MC125

MC130

MC140

MC145

MC150

MC160

MC200

Feeding port size (mm)

800×510

930×580

1060×700

1000×760

1150×800

1375×760

1100×850

1200×870

1250×950

1300×1000

1400×1070

1400×1100

1400×1200

1600×1200

2000×1500

Recommended maximum feed (mm)

450

500

580

650

650

650

700

700

800

850

860

1000

1000

1000

1200

Motor power (kw)

75

90

110

110

132

60

160

160

160-185

160-185

200

200

220

250

400

Feed outlet range (mm)

40-175

60-175

70-200

70-200

70-200

70-200

70-200

70-175

100-250

100-250

125-250

125-250

125-250

150-300

175-300

Speed (rpm)

350

330

280

260

260

260

260

230

220

220

220

220

220

220

220

Equipment weight (t)

9.5

12.2

18.6

23.3

22.3

31.5

29.5

31.5

44

45.8

54.2

63

61

88.3

137

Product size (mm)

Tightening edge discharge port CSS(mm)

Production capacity (Mtph)

0-60

40

65-85

0-75

50

85-95

0-90

60

95-125

120-155

0-105

70

115-150

140-180

50-200

155-210

170-210

210-280

190-250

175-240

0-120

80

130-170

160-210

165-215

170-225

180-235

240-310

210-275

195-270

0-135

90

150-195

180-235

190-235

190-245

205-255

265~345

235-305

210-305

0-150

100

185-215

200-260

205-265

215-280

230-285

295-375

255-330

235-325

290-380

270-370

0-185

125

210-275

250-325

255-325

265-345

275-355

345-455

310-405

285-395

350-455

325-450

385-500

400-520

340-470

0-225

150

250-325

300-390

305-385

315-410

320-405

415-525

370-480

340-475

410-535

380-525

455-590

470-610

400-555

430-610

0-260

175

290-380

350-455

355-450

370-480

375-465

475-615

425-550

385-540

470-610

435-600

520-675

540-700

460-635

495-695

630-890

0-300

200

395~500

420-545

420-540

545-685

480-625

530-690

490-680

590-765

610-795

520-720

560-790

710-1000

0-340

225

590-770

545-755

655-850

680-885

580-800

625-880

785-1105

0-375

250

650-845

600-835

725-945

750-975

640-880

685-965

885-1215

0-410

275

820-1070

745-1055

940-1320

0-450

300

815-1145

1015-1435

Product Message

Get in touch with our team in a timely manner and be happy You offer help

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.