We need a technical consultant to answer your questions?

TEL:+86 17719986188

E-mail:liam@cnshanling.com

Address: Industrial Cluster Zone of Xiuwu Economic Development Zone, Jiaozuo City, Henan Province

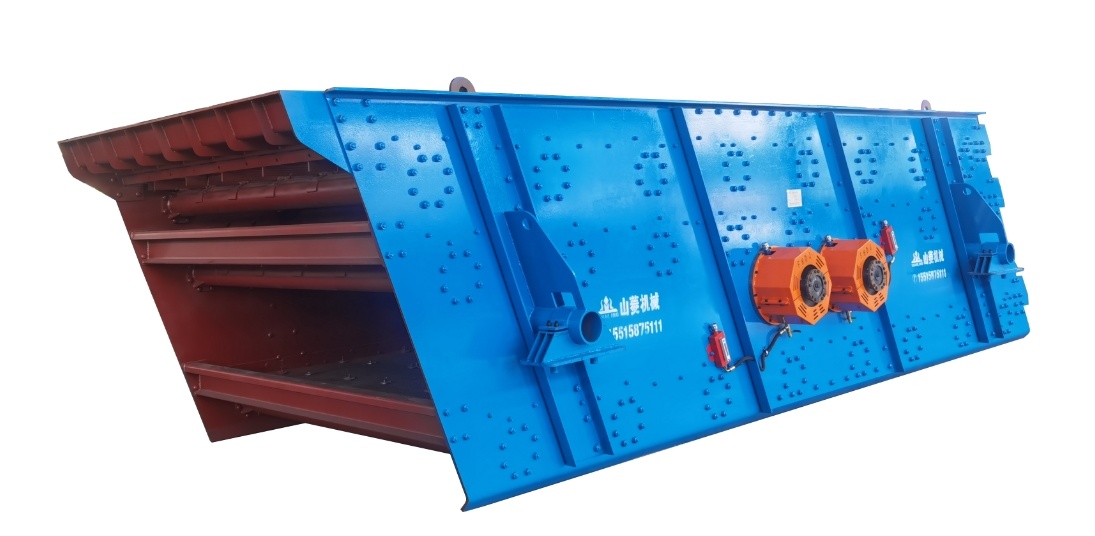

YK series circular vibrating screen

Key words:

YK series circular vibrating screen

- Product Description

- Detailed parameters

-

- Commodity name: YK series circular vibrating screen

Product Introduction

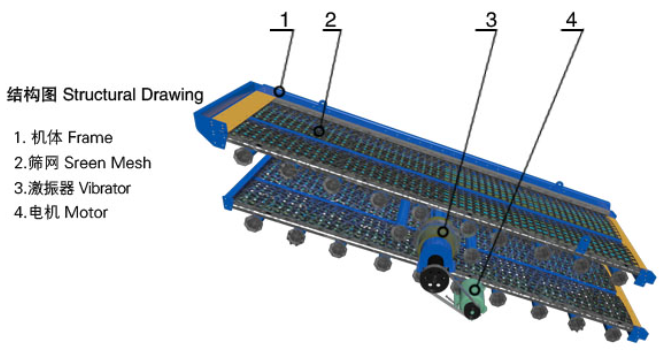

The YK series circular vibrating screen is a high-efficiency vibrating screen manufactured by our company, absorbing foreign technology. It is used in quarries for screening sand and gravel, and can also be used in coal preparation, mineral processing, building materials, power generation, and chemical industries. This inclined circular vibrating screen is an ideal screening machine for processing materials after primary and secondary crushing, and can also be used for screening final products. It uses block eccentrics as the exciting force, resulting in a strong exciting force. The screen machine beam and screen box are connected by high-strength bolts without welding. The screen machine structure is simple, and maintenance is convenient and quick. It uses a tire coupling for flexible connection and stable operation. It features high screening efficiency, large processing capacity, and a long lifespan.

Performance Characteristics

Uses block eccentrics as the exciting force, resulting in a strong exciting force. The screen machine beam and screen box are connected by high-strength bolts without welding. The screen machine structure is simple, and maintenance is convenient and quick. It uses a tire coupling for flexible connection and stable operation. It features high screening efficiency, large processing capacity, and long lifespan.

Working Principle

The motor drives the eccentric block of the exciter to rotate at high speed via a V-belt. The rotating eccentric block generates a large centrifugal force, causing the screen box to generate a circular motion with a certain amplitude. The material on the screen undergoes continuous throwing motion due to the impulse transmitted by the screen box on the inclined screen surface. In the process of the material encountering the screen surface, particles smaller than the screen holes pass through the screen, thus achieving classification.

-

model

Number of screen layers

Sieve surface inclination angle

(°)

Screen area

(m²)Vibration frequency

(r/min)Double amplitude

(mm)Processing capability

(m³/h)

Motor power

(kw)2YK1235

2

15

4.2

970

6-8

20-150

5.5

3YK1235

3

15

4.2

970

6-8

20-150

7.5

4YK1235

4

15

4.2

970

6-8

20-150

11

YK1545

1

15

6.75

970

6-8

22-150

11

2YK1545

2

17.5

6.75

970

6-8

22-150

15

3YK1545

3

17.5

6.75

970

6-8

22-150

15

4YK1545

4

17.5

6.75

970

6-8

22-150

18.5

YK1860

1

20

10.8

970

6-8

32-350

15

2YK1860

2

20

10.8

970

6-8

32-350

18.5

3YK1860

3

20

10.8

970

6-8

32-350

18.5

4YK1860

4

20

10.8

970

6-8

32-350

22

YK2160

1

20

12.6

970

6-8

66-720

18.5

2YK2160

2

20

12.6

970

6-8

66-720

22

3YK2160

3

20

12.6

740

6-8

66-720

30

4YK2160

4

20

12.6

740

6-8

66-720

30

YK2460

1

20

14.4

740

6-8

75-750

22

2YK2460

2

20

14.4

740

6-8

75-750

30

3YK2460

3

20

14.4

740

6-8

75-750

30

4YK2460

4

20

14.4

740

6-8

75-750

37

YK3060

1

20

17.4

740

6-8

200-900

30

2YK3060

2

20

17.4

740

6-8

200-900

37

3YK3060

3

20

17.4

740

6-8

200-900

45

4YK3060

4

20

17.4

740

6-8

200-900

45

YK3075

1

20

22

840

6-8

840-1080

37

2YK3075

2

20

22

840

6-8

840-1080

45

3YK3075

3

20

22

840

6-8

840-1080

55

2YKD3075

2

20

22

840

6-8

100-1080

2×30

3YKD3075

3

20

22

840

6-8

100-1080

2×37

2YKD3675

2

20

22

840

6-8

100-1300

2×45

3YKD3675

3

20

22

840

6-8

100-1300

2×45

Previous

Next

Product Message

Get in touch with our team in a timely manner and be happy You offer help

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.