We need a technical consultant to answer your questions?

TEL:+86 17719986188

E-mail:liam@cnshanling.com

Address: Industrial Cluster Zone of Xiuwu Economic Development Zone, Jiaozuo City, Henan Province

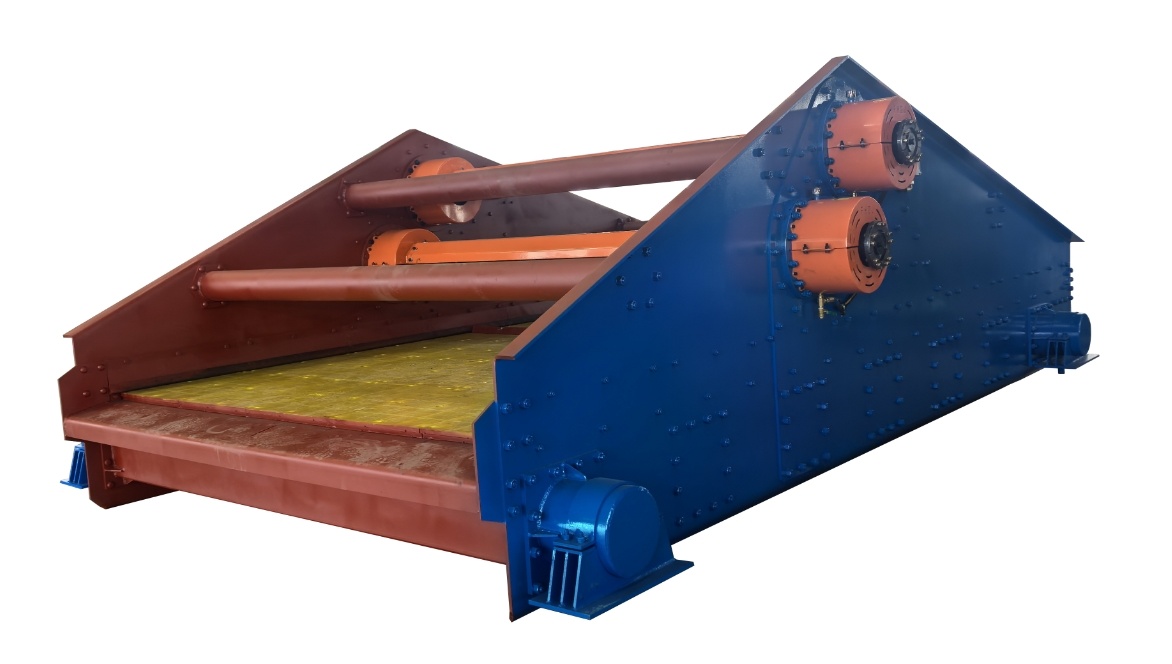

ZK Series Linear Dewatering Screen

Key words:

ZK Series Linear Dewatering Screen

- Product Description

- Detailed parameters

-

- Commodity name: ZK Series Linear Dewatering Screen

Product Introduction

The ZK series linear vibrating screen is a high-efficiency vibrating screen manufactured using German technology. It is widely used in coal, metallurgy, power, building materials, and light industries for dry or wet grading, dehydration, de-sludging, and de-mediation of medium and fine-grained materials.

Performance Characteristics

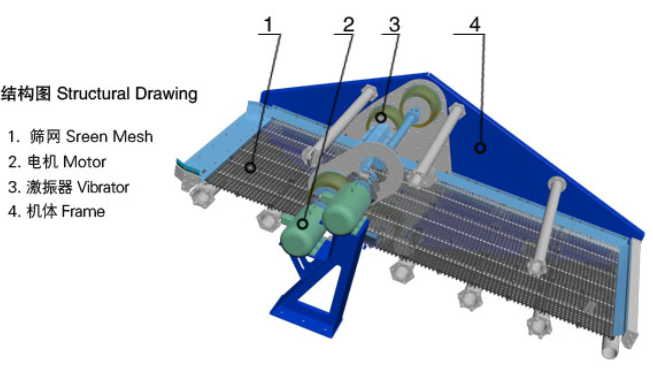

1. Uses block eccentricity as the exciting force, resulting in a strong exciting force;

2. The screen beam and screen box are connected using high-strength bolts, without welding;

3. The screen machine has a simple structure and is easy and quick to maintain;

4. Uses a tire coupling for flexible connection and stable operation;

5. High screening efficiency, large processing capacity, and long lifespan.

Working Principle

The linear vibrating screen uses a dual-motor drive. When the two motors rotate synchronously and in opposite directions, the exciting forces generated by their eccentric blocks cancel each other out in the direction parallel to the motor axis and combine into a resultant force in the direction perpendicular to the motor axis. Therefore, the movement trajectory of the screen machine is a straight line. The two motor shafts have an angle relative to the screen surface. Under the combined action of the exciting force and the weight of the material, the material is thrown up on the screen surface and moves forward in a jumping manner, thus achieving the purpose of screening and grading the material.

-

Sieve

Model Area (m²)

Screen Aperture Size

(mm)Screen Mesh Structure

Feed Particle Size

(mm)Processing Capacity

(t/h)Motor Power

(kw)

ZK1022

2.25

0.25-50

<250

4.5-90

3x2

ZK1230

3.6

0.25-50

<250

7.2-144

4x2

ZK1237

4.5

0.25-50

<250

9.0-180

5.5x2

ZK1437

5.25

0.25-50

<250

12.0-250

5.5x2

ZK1445

6.3

0.25-50

<250

12.6-252

7.5x2

ZK1637

6

0.25-50

<250

12.0-240

5.5x2

ZK1645

7.32

0.25-50

<250

14.4-280

7.5x2

ZK1837

6.75

0.25-50

<250

14.4-270

11x2

ZK1845

8.1

0.25-50

<250

16.2-324

11x2

ZK1852

9.45

0.25-50

<250

18.9-378

11x2

ZK2045

9

0.25-50

<250

16.2-324

11x2

ZK2052

10.5

0.25-50

<250

21.0-420

11x2

ZK2060

12

0.25-50

<250

24.0-480

15x2

ZK2445

10.8

0.25-50

<250

21.6-432

15x2

ZK2452

12.6

0.25-50

<250

25.2-504

15x2

ZK2460

14.4

0.25-50

<250

28.8-576

18.5x2

ZK3045

13.5

0.25-50

Weaving, Stitching,

Stamping, Rubber,

Polyurethane Array Mesh

<250

27.0-540

18.5x2

ZK3052

15.75

0.25-50

<250

31.4-628

22x2

ZK3060

18

0.25-50

<250

17.5-525

22x2

ZK3645

16.2

0.25-50

<250

37.8-756

30x2

ZK3652

18.9

0.25-50

<250

43.2-846

30x2

ZK3660

21.6

0.25-50

<250

43.2-846

30x2

ZK3675

27

0.25-50

<250

54.0-1080

37x2

2ZK1022

2.25

0.25-50

<250

4.5-90

4x2

2ZK1230

3.6

0.25-50

<250

7.2-144

5.5x2

2ZK1237

4.5

0.25-50

<250

9.0-180

7.5x2

2ZK1437

2.25

0.25-50

<250

12.0-250

7.5x2

2ZK1445

6.3

0.25-50

<250

12.6-252

11x2

2ZK1637

6

0.25-50

<250

12.0-240

11x2

2ZK1645

7.32

0.25-50

<250

14.4-280

11x2

2ZK1837

6.75

0.25-50

<250

14.4-270

15x2

2ZK1845

8.1

0.25-50

<250

16.2-324

15x2

2ZK1852

9.45

0.25-50

<250

18.9-378

15x2

2ZK2045

9

0.25-50

<250

16.2-324

18.5x2

2ZK2052

10.5

0.25-50

<250

21.0-420

18.5x2

2ZK2060

12

0.25-50

<250

24.0-480

22x2

2ZK2445

10.8

0.25-50

<250

21.6-432

22x2

2ZK2452

12.6

0.25-50

<250

25.2-504

22x2

2ZK2460

14.4

0.25-50

<250

28.8-576

22x2

2ZK3045

13.5

0.25-50

<250

27.0-540

30x2

2ZK3052

15.75

0.25-50

<250

31.4-628

37x2

2ZK3060

18

0.25-50

<250

17.5-525

37x2

2ZK3645

16.2

0.25-50

<250

37.8-756

45x2

2ZK3652

18.9

0.25-50

<250

43.2-846

45x2

2ZK3660

21.6

0.25-50

<250

43.2-846

45x2

Previous

Product Message

Get in touch with our team in a timely manner and be happy You offer help

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.