We need a technical consultant to answer your questions?

TEL:+86 17719986188

E-mail:liam@cnshanling.com

Address: Industrial Cluster Zone of Xiuwu Economic Development Zone, Jiaozuo City, Henan Province

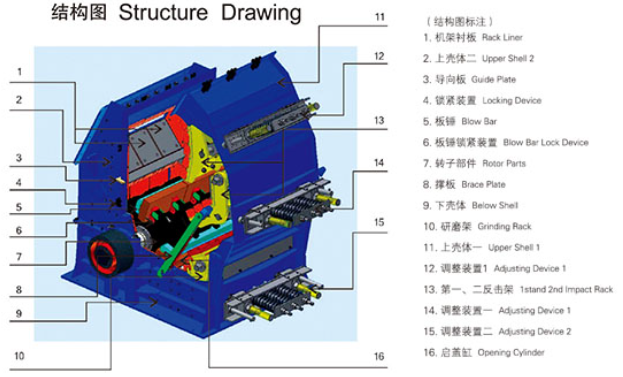

NP series European-style impact crusher

Key words:

NP series European-style impact crusher

- Product Description

- Detailed parameters

-

- Commodity name: NP series European-style impact crusher

Product Introduction

Generally used for crushing materials with medium hardness or below and low abrasion resistance. It can be used for coarse crushing, medium crushing, and fine crushing, with a large crushing ratio and good finished particle shape. Mainly applied in the fields of metal mining, non-metal mining, sand and gravel aggregates, construction recycling, and chemical industry.

Performance Characteristics

Rotor Optimization Design: Optimized heavy-duty design of the rotor increases rotational inertia and improves equipment capacity; the unique wedge block hammer locking device is convenient and safe to disassemble.

Flexible Configuration: All models have two and three chambers. Different chamber types and wear-resistant hammers can be selected according to different applications to achieve a better output ratio.

Modular Design of Wearing Parts: By reasonably designing and arranging wear-resistant liner plates, the number of wearing parts is minimized. They can be interchanged according to the degree of wear of each part, improving the utilization rate of wearing parts and reducing inventory.

Diversity: Flexible switching between fixed and mobile operations.

Working Principle

The series of impact crushers utilize impact energy to crush materials. During operation, driven by the motor, the rotor of the impact crusher rotates at high speed. After the material enters, it collides with the hammers on the rotor and is crushed. Then, it is impacted again on the liner plate for further crushing, finally being discharged from the discharge port. Users can adjust the gap between the impact frame and the rotor frame to change the particle size and shape of the discharged material.

-

model

Inlet size

(mm)

Maximum feed particle size

(mm)

Rotor size

(mm)

Maximum speed

(rpm)

Motor power

(kw)

Equipment weight

(kg)

NP1110

1020×820

600(300)

1100×1000

800

132-160

9250

NP1213

1320×880

600(350)

1200×1300

700

200-250

13000

NP1315

1540×930

600(400)

1300×1500

700

280-355

16500

NP1520

2040×995

700(400)

1500×2000

600

400-630

27100

NP1210

1020×1080

800(400)

1200×1000

700

160

12800

NP1313

1320×1200

900(450)

1300×1300

700

200-250

18000

NP1415

1540×1320

1000(600)

1400×1500

600

250-315

22350

NP1620

2040×1630

1300(700)

1600×2000

500

400-500

41300

NP2023

2310×1980

1500(800)

2000×2300

500

900-1200

74500

model

90% of the product particle size is less than the specified sieve hole size (square hole)

15 20

25

30 40

50

60

80

100

120

NP1110

90-110

100-120

120-150

120-160

140-190

180-210

200-250

220-280

250-300

280-300

NP1213

160-170

180-200

200-250

200-280

210-300

220-320

250-350

280-380

300-400

350-400

NP1315

200-220

220-250

120-150

250-300

280-360

300-390

315-410

350-480

430-490

430-500

NP1520

300-350

350-400

380-450

400-480

410-500

450-550

500-620

550-700

630-750

700-780

model 40

50

60

80

100

125

150

200

250

300

NP1210

120-150

150-190

180-220

200-260

230-280

250-320

280-350

350-380

NP1313

160-190

190-240

240-270

250-310

280-360

300-400

360-450

430-500

NP1415

200-240

235-300

275-340

300-410

350-460

400-500

445-510

500-600

NP1620

295-365

360-450

400-500

500-625

535-700

575-750

625-780

755-950

NP2023

600-750

750-855

800-1000

1000-1320

1050-1500

1150-1750

1300-1800

1550-2000

1750-2050

1800-2100

Previous

Next

Product Message

Get in touch with our team in a timely manner and be happy You offer help

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.