We need a technical consultant to answer your questions?

TEL:+86 17719986188

E-mail:liam@cnshanling.com

Address: Industrial Cluster Zone of Xiuwu Economic Development Zone, Jiaozuo City, Henan Province

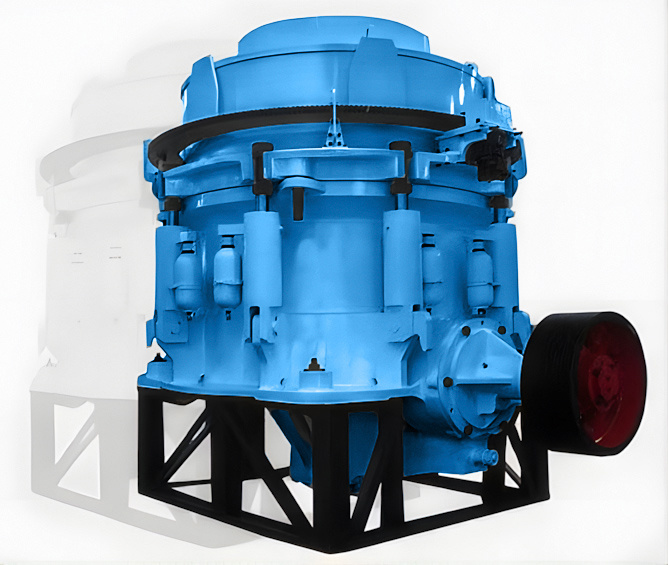

HP series multi-cylinder cone crusher

Key words:

HP series multi-cylinder cone crusher

- Product Description

- Detailed parameters

-

- Commodity name: HP series multi-cylinder cone crusher

Production Capacity

The production capacity table can be used as a preliminary selection tool for HP cone crushers. The data in the table is applicable to materials with a loose density of 1.6t/m³, feeding with screening of particles smaller than the discharge port size, and open-circuit operation. Under conditions with a higher content of fine particles in the feed and closed-circuit operation, the equipment capacity is 15%-30% higher than that of open-circuit operation. As an important component in the production circuit, the performance of the crusher partly depends on the correct selection and operation of the feeder, conveyor belt, vibrating screen, support structure, motor, transmission device, and hopper, etc. Note that the following factors can improve the production capacity and performance of the crusher.

Working Principle

1. A new series of cone crushers with superior performance.

2. Fixed main shaft design and optimized crushing chamber shape, increasing crushing output.

3. More stable product particle size distribution and better particle shape.

4. Full hydraulic standard configuration, simple operation and flexible adjustment.

5. Independently designed single-acting cylinder, more stable system performance.

6. New integrated base, simplifying installation steps.

7. Improved appearance structure, combining functionality and aesthetics.

Internal Structural Parts

1. Locking Screw

14. Counterweight Guard Plate

2. Feed Hopper

15. Tramp Iron Release Assembly

3. Concave

16. Eccentric Bushing

4. Adjusting Ring

17. Eccentric

5. Moving Cone Sphere

18. Lower Moving Cone Bushing

6. Main Frame

19. Moving Cone

7. Spherical Bearing

20. Moving Cone Liner Plate

8. Upper Moving Cone Bushing

21. Concave Liner Plate

9. Transmission Shaft

22. Hydraulic Adjustment Motor

10. Outer Transmission Shaft Bushing

23. Locking Cylinder

11. Large and Small Gears

24. Cutting Ring

12. Main Shaft

25. Feed Plate

13. Eccentric Thrust Bearing

-

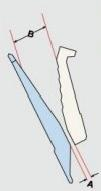

Standard type

Short-headed

Crusher

model

Crusher

Cavity

Tighten edge feeding port

A′(mm)

Open edge feeding port

B2 (mm)

Minimum discharge port

C3 (mm)

Tighten edge feeding port

A′(mm)

Open edge feeding port

B2 (mm)

Minimum discharge port

C3 (mm)

HP100

ultra-thin

thin

medium

thick

extra-thick

20

50

70

100

150

50

100

97

124

176

6

9

9

13

21

HP200

thin

medium

thick

extra-thick

95

125

185

128

156

208

14

17

19

25

54

76

66

70

114

6

6

10

1. The minimum discharge port refers to the minimum discharge port that can be achieved without causing the adjustment ring to jump. It changes with the ore properties and operating conditions.

2. "B" is the corresponding tight edge feeding port at the minimum discharge port "A".

3. According to the equipment specifications and physiology, the maximum feed size is 80% to 100% of the "B".

HP300

thin

medium

thick

extra-thick

107

150

211

233

148

190

240

267

13

16

20

25

25

53

77

72

100

123

6

8

10

HP400

thin

medium

thick

extra-thick

111

198

252

299

164

245

292

333

14

20

25

30

40

52

92

104

107

143

6

8

10

HP500

thin

medium

thick

extra-thick

133

204

286

335

182

246

322

372

16

20

25

30

40

57

95

105

116

152

8

10

13

HP800

thin

medium

thick

extra-thick

219

267

297

353

264

308

340

375

16

25

30

23

33

92

155

98

150

210

5

10

13

Ton/hour

T/H

Tighten edge discharge port

6mm

(1/4")

8mm

(5/6")

10mm

(3/8")

13mm

(1/2")

16mm

(5/8")

19mm

(3/4")

22mm

(7/8")

25mm

(1")

32mm

(11/4")

28mm

(11/2")

45mm

(13/4")

51mm

(2")

HP100

t/h

45-55

50-60

55-70

60-80

70-90

75-95

80-100

85-110

100-140

HP200

t/h

90-120

120-150

140-180

150-190

160-200

170-220

190-235

210-250

HP300

t/h

115-140

150-185

180-220

200-240

220-260

230-280

250-320

300-380

350-440

HP400

t/h

140-175

185-230

225-280

255-320

275-345

295-370

325-430

360-490

410-560

465-630

HP500

t/h

175-220

230-290

280-350

320-400

345-430

365-455

405-535

445-605

510-700

580-790

HP800

t/h

260-335

325-425

385-500

435-545

470-600

495-730

545-800

600-950

690-1050

785-1200

Previous

Product Message

Get in touch with our team in a timely manner and be happy You offer help

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.